Circular Products

Designed for Long Life

There is no sustainable future without efficiently circulating natural resources and conserving biological diversity. Our mission is to keep our products and materials within the circular economy, aiming for all products to be circular by 2030.

WHAT IS A CIRCULAR PRODUCT

While waiting for a standardised definition, we mean that a circular product is an attractive, timeless product with a long lifespan that can stand up to years of hard use. It shall consist of reused, recycled, or renewable material. When the product is damaged, it shall be possible to repair it. When it is no longer needed, it shall be possible to disassemble it into parts that can be reused, or material recycled. Preferably, recycling should occur in closed loops, preserving the material’s value.

In a circular economy products, components and materials circulate in a loop, with only a small fraction ending up as waste.

THE WAY WE DESIGN

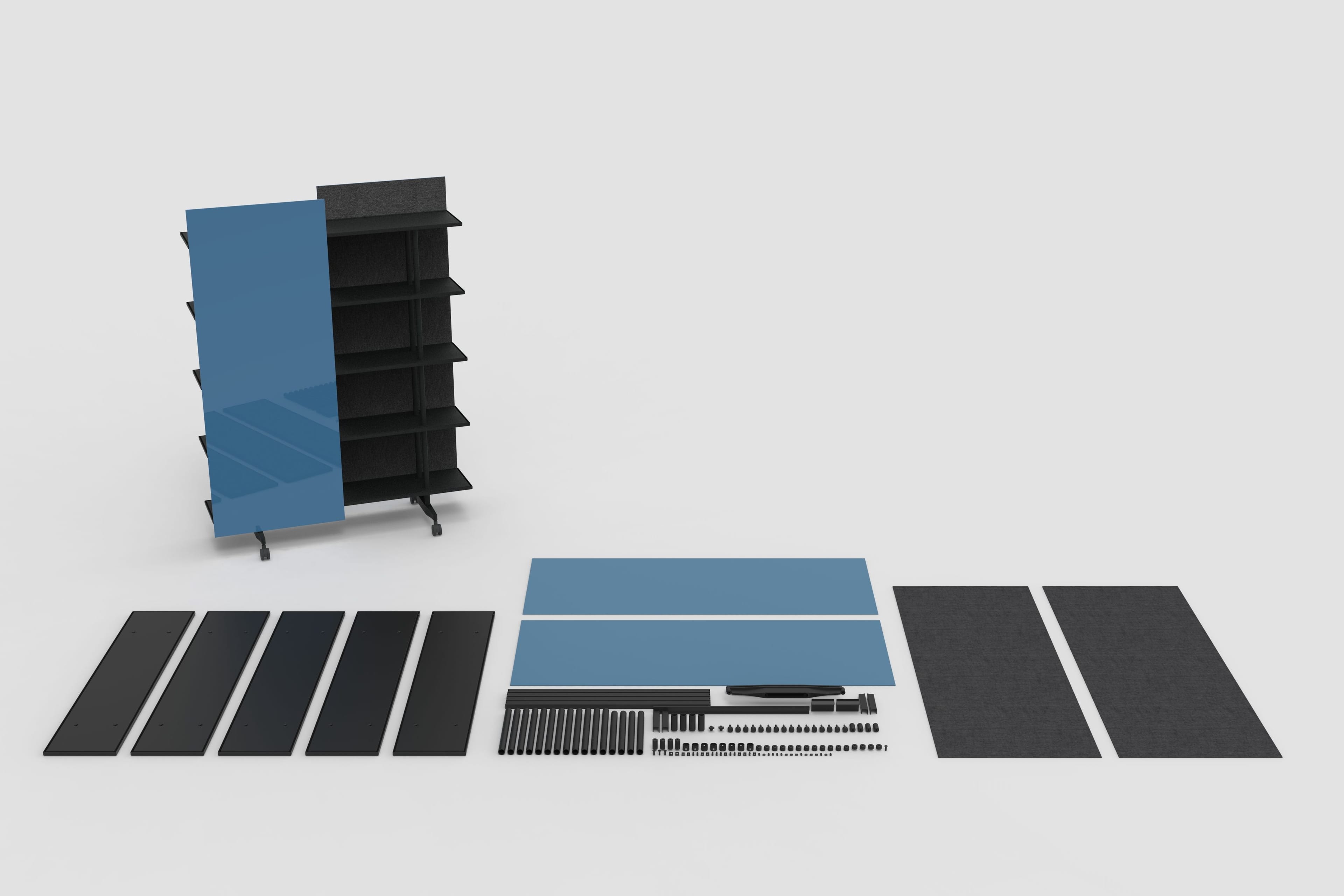

Circularity starts in the design phase. Our core business idea has always been to create well-designed products from high-quality materials, products that allow flexible use and are attractive enough to survive a move from one office to another. During the construction phase we strive for separability, use of recycled and recyclable materials, not using any excess material, and allowing repair of parts that might be worn down.

A08 is designed for easy separability, allowing parts to be replaced and reused or recycled individually.

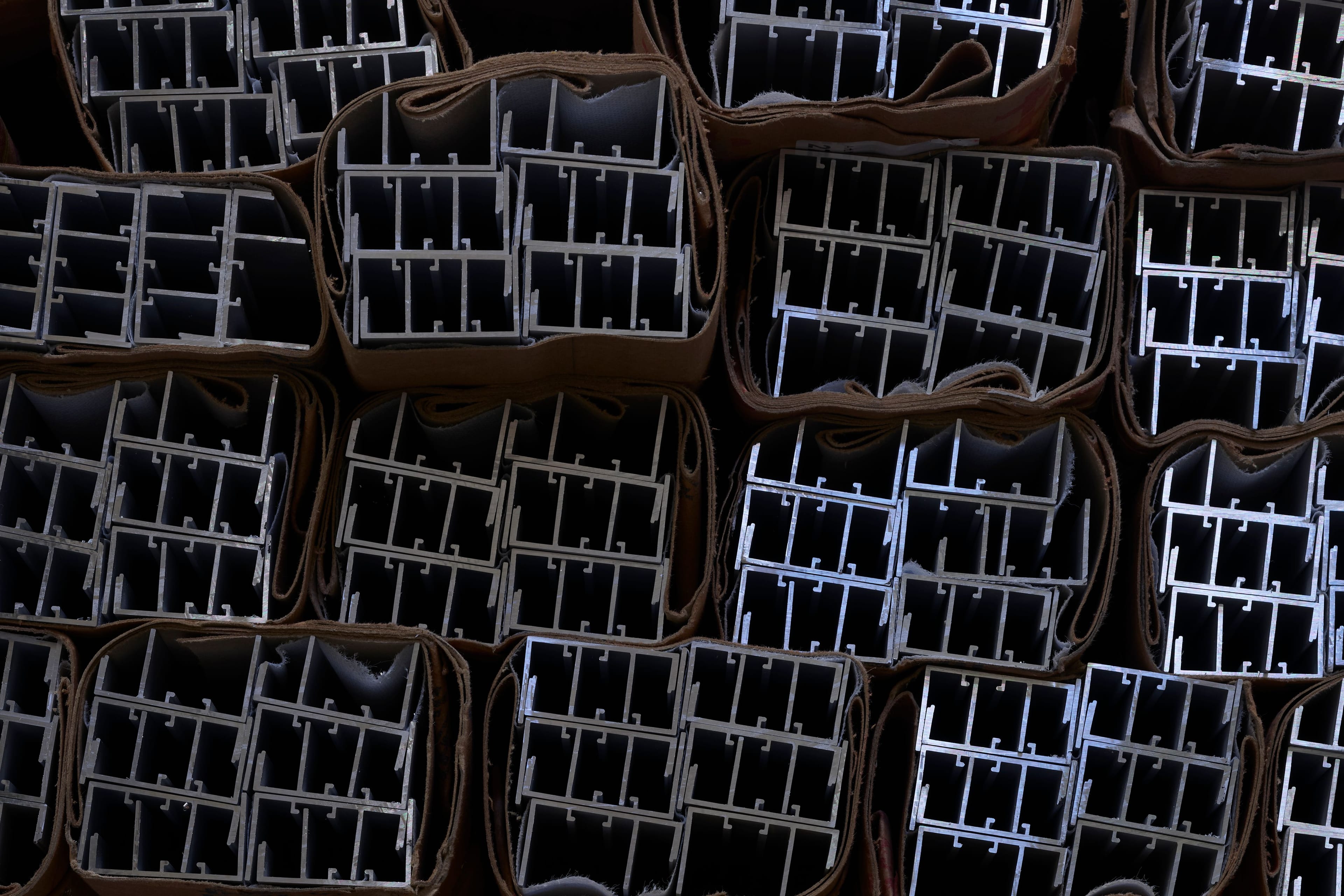

MATERIALS WE USE

To ensure our products have a long lifespan, we select high-quality materials such as aluminium and solid wood. As an example, the e3 ceramic steel surface we use has a forever warranty. Elimination of hazardous substances is a necessity for circularity. Therefore, we work with certifications such as EU Ecolabel, Möbelfakta and Byggvarubedömningen, all with strict requirements on chemical content. Renewable materials are not circular unless they are sustainably produced. We choose wood certified with FSC® and wool certified with EU Ecolabel.

Share of FSC® certified wood used in our products.

Overall, we are committed to maximising the use of recycled materials and recovered components in our products. Our long-term ambition is to only offer fabrics that are recycled and recyclable. For example, the Cura Screen fabric we use meets these criteria. The backing of the fabric is a unique mono-material, which makes it suitable for material recycling. So far, more than 40% of the filling, fibreboard, aluminum foil, and cast aluminium we use are made from recycled materials. The packaging material is up to 80% recycled.

PRODUCTION

We aim to make our production circular. Waste is minimised according to our target to constantly move waste up the waste hierarchy. We manage returns and take-backs, ensuring products are given a second life. We also handle gently used items from fairs, showrooms, and photoshoots, reintegrating them back into circulation. This approach helps us reduce waste and maximise the value of our resources.

Waste from the Swedish production, in tonnes.

USE — STAY IN MARKET

We know that the technical lifespan of many of our products exceeds 30 years. Long-term relationships with clients show that our writing boards have been used even longer and remain in good shape. However, we often see products being thrown away while still functioning. Therefore, we encourage the use, reuse and resale of our products to maximise their technical lifespan. We support our clients in how to clean and move the products, and we provide spare parts upon request.

COLLECT — RETURN TO MARKET

In a future circular economy, rental business models will play an important role. However, as long as products continue to change owners, all participants in the value chain must collaborate to achieve true circularity. As a manufacturer, we are preparing to take responsibility for LINTEX products when they reach their end-of-life.

Currently, not all of our products can be fully disassembled. We are systematically working through our product range to make the necessary changes. This includes redesigning products to be modular, developing machinery to aid in the separation process, and launching a take-back service. We have developed tools that enable us to separate glassboards, where glass and steel are laminated together.

Take back is offered for Edge floor and table screens, with more products to be included going forward. Product parts will be used for remanufacturing or properly recycled. We aim to close the loop for all products sold by Lintex.

RETAKE — HOW DOES IT WORK

In this first phase, the free take-back service for Edge floor and table screens is available in Sweden, Norway, Denmark and Finland. To streamline the process, we only accept standardised sizes of products manufactured after 2013, with a minimum of 10 screens for each take-back. End users are responsible for removing feet and fittings and placing the products on a pallet, while we organise the transportation. If you, as an end user, have products that meet these standards and you want them taken care of, let us know.

Download the retake form here and email it to

hereinfo@lintex.com.

REDRESS — HOW DOES IT WORK

We offer a fabric redress service for Edge floor and table screens, as well as for our Unit movable walls. Customers can hand in screens for redressing, and we provide the option to recycle some products while redressing others, depending on customer needs.

Please contact us at info@lintex.com for a quote.

Text: Sara Gripstrand, Sustainability Manager.

Photos: Brendan Austin